Distribution of Iron ore

Distribution of Key Natural Resources

Iron ore

Iron ore is one of the most important mineral resources in the world, forming the backbone of industries and modern infrastructure. It is the primary raw material for the production of iron and steel. The global demand for iron ore has grown significantly due to rapid industrialization, urbanization, and technological advancements. Majority of the iron ore that is mined is used in iron and steel industry.

Types of Iron Ore

Iron ore exists in different forms based on mineral composition, iron content, and physical properties. The major types include:

Hematite (Fe₂O₃)

- Contains 70% iron, making it one of the most important ores for iron production.

- Has a reddish-brown color.

- Found in massive deposits worldwide.

- Examples of major deposits: Australia, Brazil, India, Russia, and China.

- In India, it is mainly found in Odisha, Jharkhand, Chhattisgarh and Andhra Pradesh.

Magnetite (Fe₃O₄)

- Contains 60-70% iron.

- Has magnetic properties, making it easy to process.

- Mostly found in banded iron formations (BIFs).

- Major deposits: Sweden, Canada, Russia, and the USA.

- In India, this type of ore is found in Karnataka, Andhra Pradesh, Tamil Nadu

Limonite

- Contains 40-60% iron but has high moisture content.

- Yellowish-brown in color.

- Often found in weathered iron ore deposits.

- Main deposits: India, Brazil, and the USA.

- In India, it is mainly found in the Kangra valley, Mirzapur and Gharwal region.

Siderite (FeCO₃)

- Contains 30-48% iron and has carbonate minerals.

- Less commonly used due to lower iron content.

- is self-fluxing due to the presence of lime.

- Found in hydrothermal veins and sedimentary rocks.

- Major deposits: Austria, China, and Germany.

Extraction of Iron ore

Iron ore is mined from the deposits whether they are near to the surface or underground. Two types of mining methods are used:

- Open-Pit mining: basically used for large and shallow deposits. The extraction goes from top to bottom.

- Underground mining: basically used for the reserve which are located deep inside the earth surface. The miners goes inside the mine to extract the raw material

Open-Pit mine

Underground mine

Once the ore is mined, the iron is retrieved from the ore by the process of smelting.

Smelting

Smelting is a metallurgical process in which iron ore is heated at high temperatures in the presence of a reducing agent (usually coke) and flux (limestone). This process removes oxygen and impurities from iron ore, yielding molten iron.

Beneficiation is a process of increasing the concentration of iron in ore by chemical treatment and thermal processes.

A blast furnace is a tall, cylindrical structure used for smelting iron ore. The process takes place in different zones within the furnace. a mixture of Iron ore, coke and limestone is fed from the top of the furnace and the blast of hot air is pushed from the bottom through tuyeres (air nozzles) of the furnace.

- blast of hot air speeds up the combustion and maintains higher temperature.

- coke acts as the reducing agent and reduces the iron ore to produce the iron

- limestone act as a flux which removes the impurities such as sulphur from the ore.

- the final products settle down at the bottom in the form of Pig iron and slag.

Basic Reactions:

Coke reacts with hot air to produce carbon-monoxide

2 C(s) + O2(g) → 2 CO(g)

As the iron ore fall down the furnace, iron is reduced in several steps. At top where temperature is between 200-700°C,

3 Fe2O3(s) + CO(g) → 2 Fe3O4(s) + CO2(g)

Further down the furnace at temperature of 850°C,

Fe3O4(s) + CO(g) → 3 FeO(s) + CO2(g)

At the bottom of the furnace where is temperature is around 1200°C,

FeO(s) + CO(g) → Fe(s) + CO2(g)

Limestone breaks down into calcium oxide and carbon dioxide.

CaCO3(s) → CaO(s) + CO2(g)

CaO combines with various impurities to form slag.

SiO2 + CaO → CaSiO3

The pig iron produced has a relatively high carbon content of around 4–5% and usually contains too much sulphur, making it very brittle, and of limited immediate commercial use. The sulphur is removed by using calcium oxide to produce cast iron.

FeS + CaO + C = CaS + FeO + CO

Some of the common impurities include Silica, Sulphur and Phosphorus.

Steel: contains carbon content upto 2%

Stainless steel: A steel alloy containing chromium, nickel, manganese, molybdenum and other minerals.

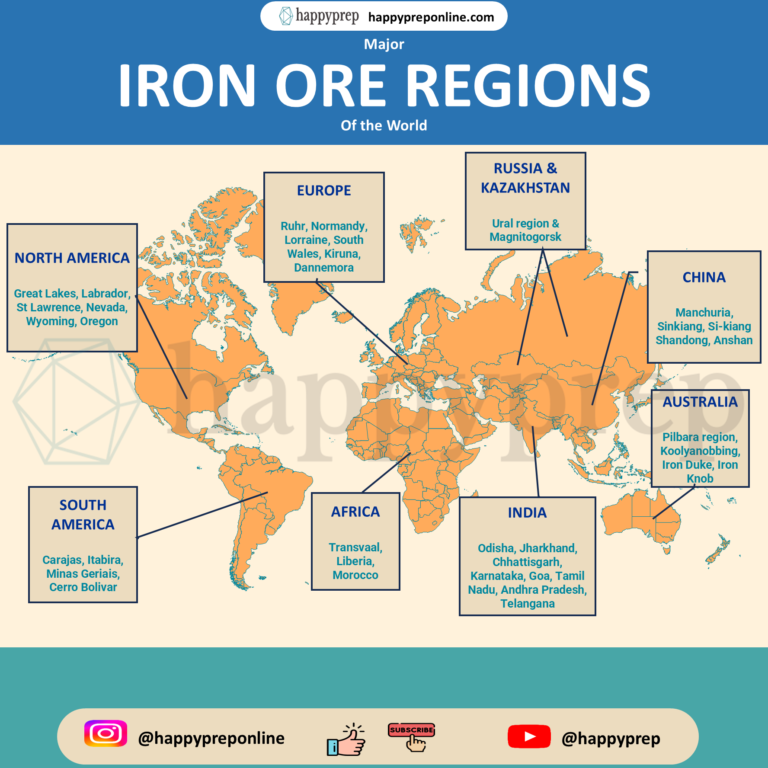

Distribution of Iron Ore around the world!

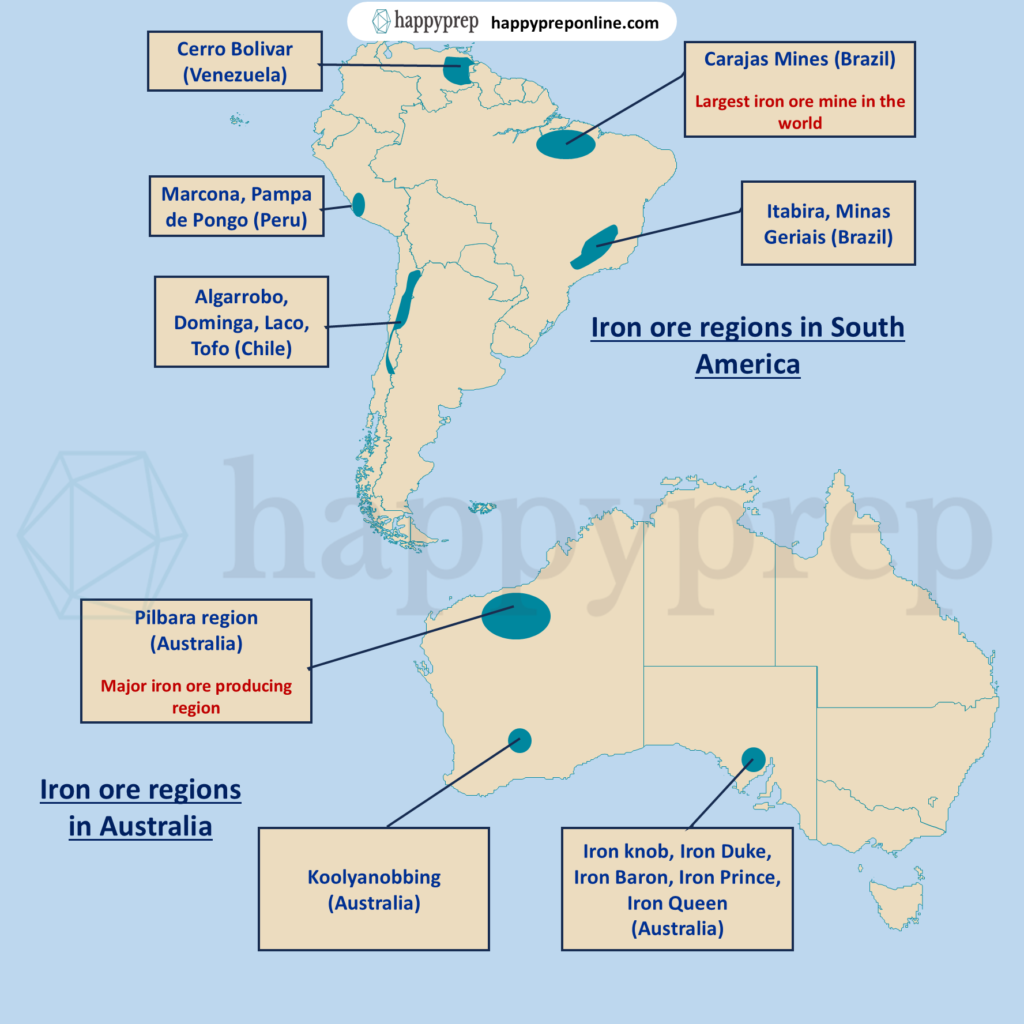

Distribution of Iron Ore in South America and Australia

South America

- Carajas mine is the largest iron ore mine in the world. Minas Geriais is another important mine in Brazil.

- Brazil is the 3rd biggest producer of iron ore.

- Small reserves are found in Chile and Peru.

Australia

- Pilbara region is the major iron ore producing region in Australia

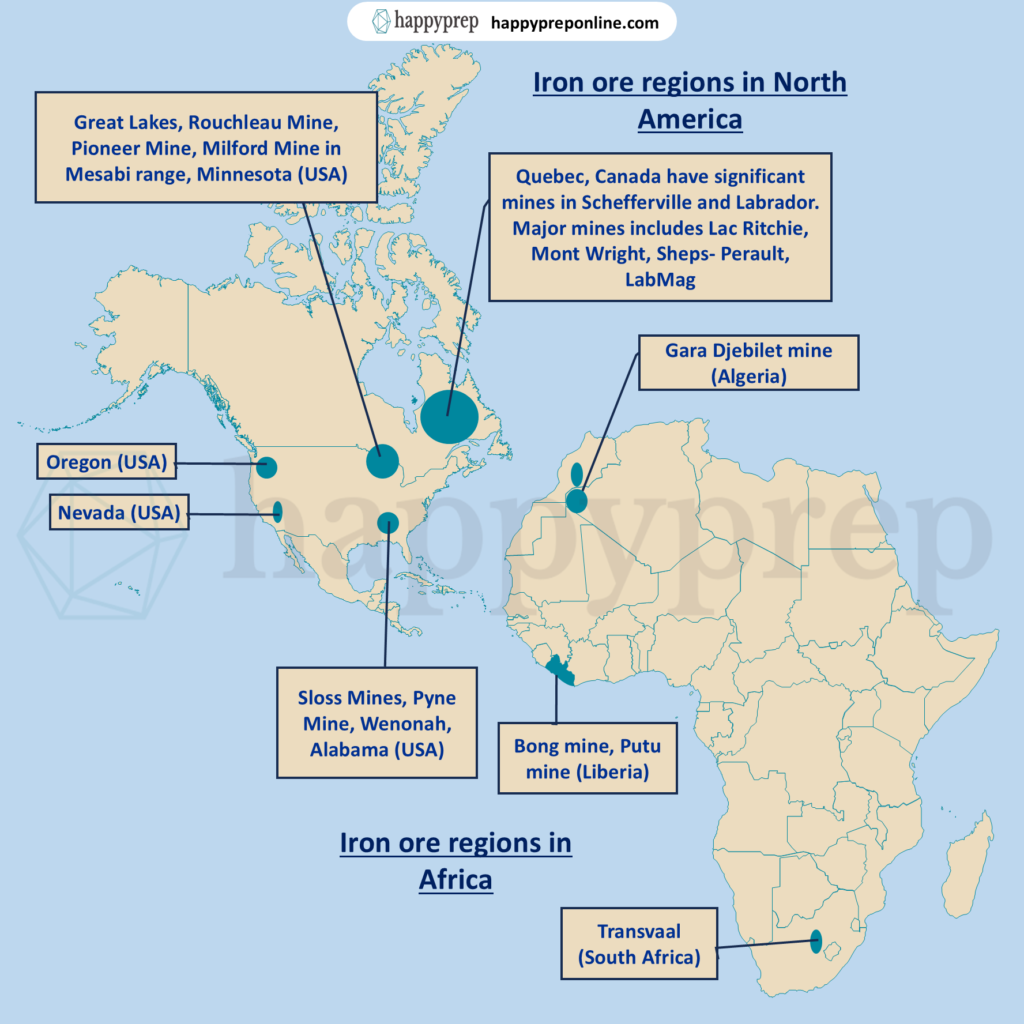

Distribution of Iron Ore in North America and Africa

North America

- Mesabi range, Great Lakes region is the major iron ore producing region.

- Region around Quebec, Canada and Labrador are also rich in iron ore

Africa

- Africa does not have a significant reserve of iron ore except few regions of Algeria, Liberia and Morocco.

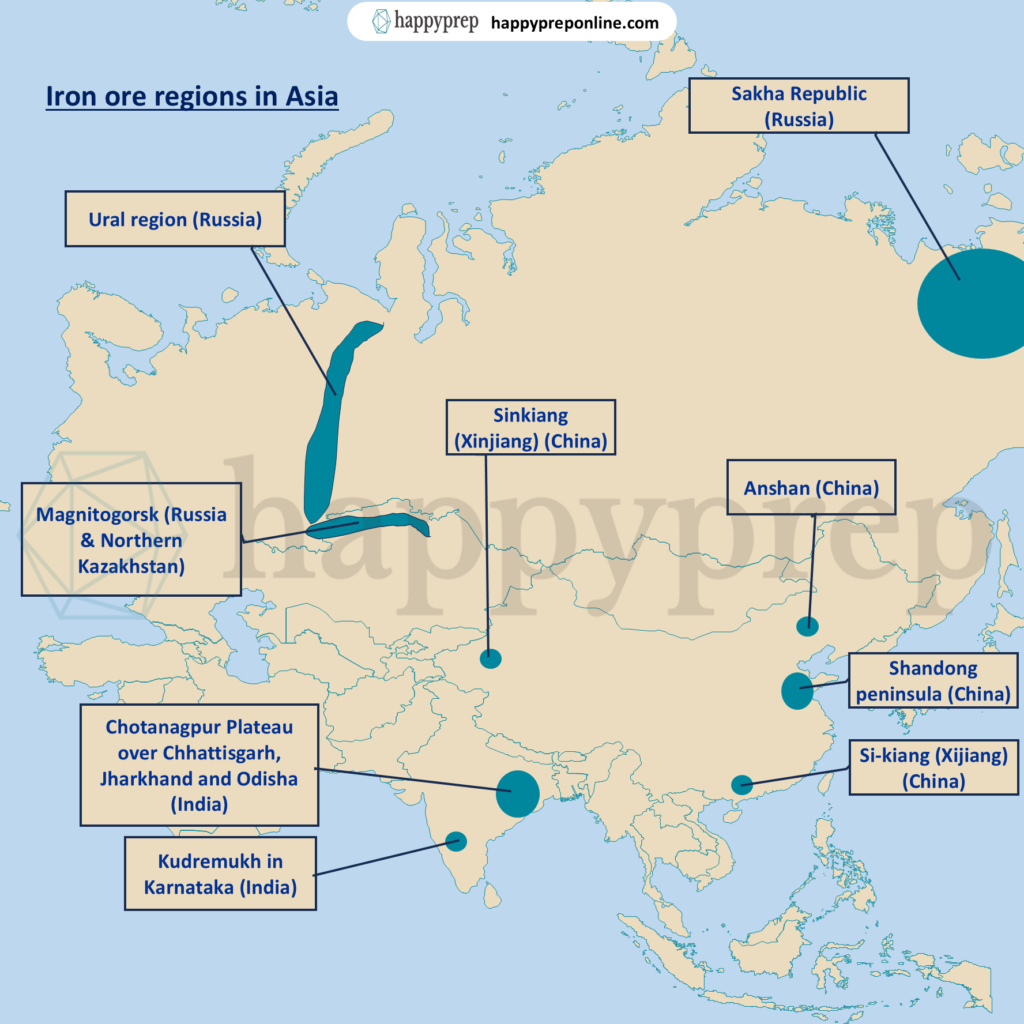

Distribution of Iron Ore in Asia

Russia

- Ural region in the west and Sakha republic in the east are the major regions with production of iron ore.

- Magnitogorsk region in northern Kazakhstan and Southern-Russia is also rich in minerals

China

- Anshan region and Shandong peninsula are the major regions of iron ore production.

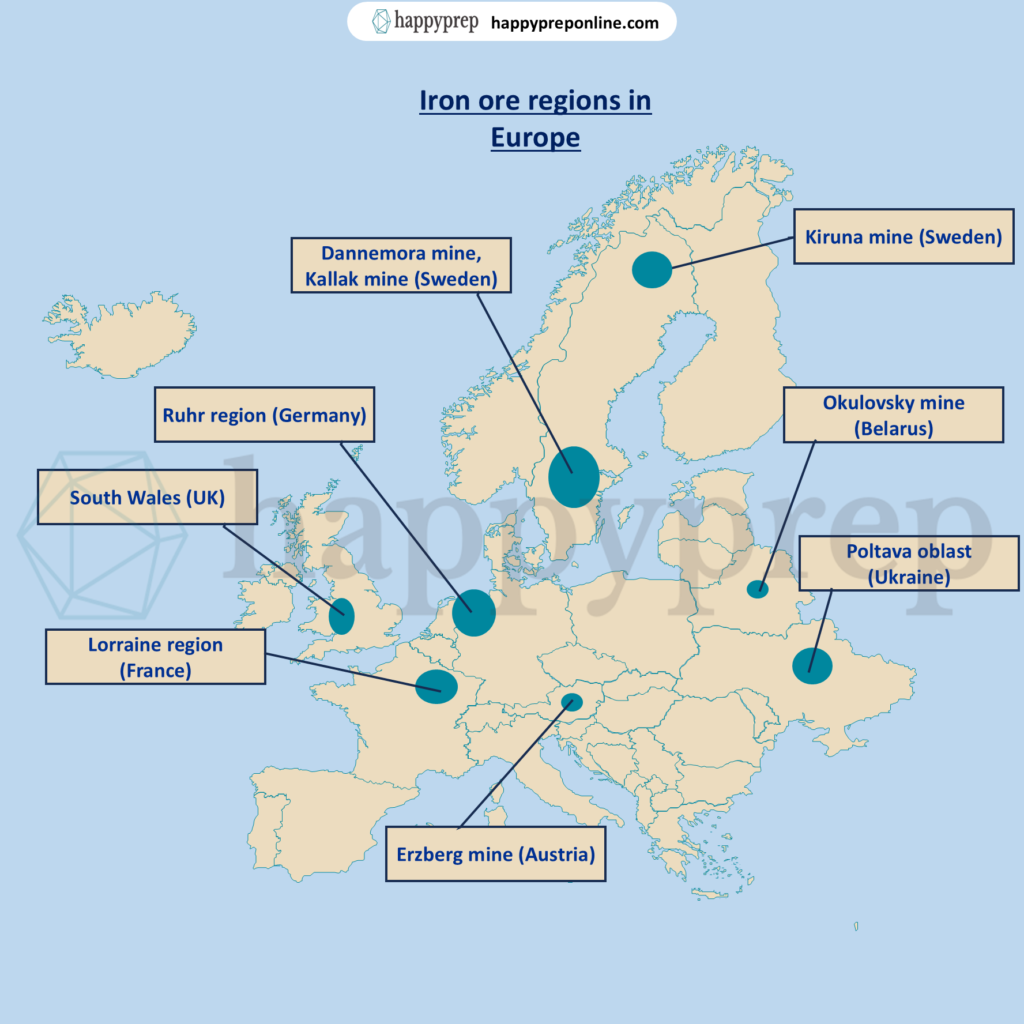

Distribution of Iron Ore in Europe

Europe

- Ruhr region is one of the mineral rich region in Europe. It can be justified by the presence of automobile industries in this region.

- Other important regions include South Wales in UK.

- Some important mines of Europe includes Dannemora mine, Kiruna mine of Sweden, Poltava oblast in Ukraine.

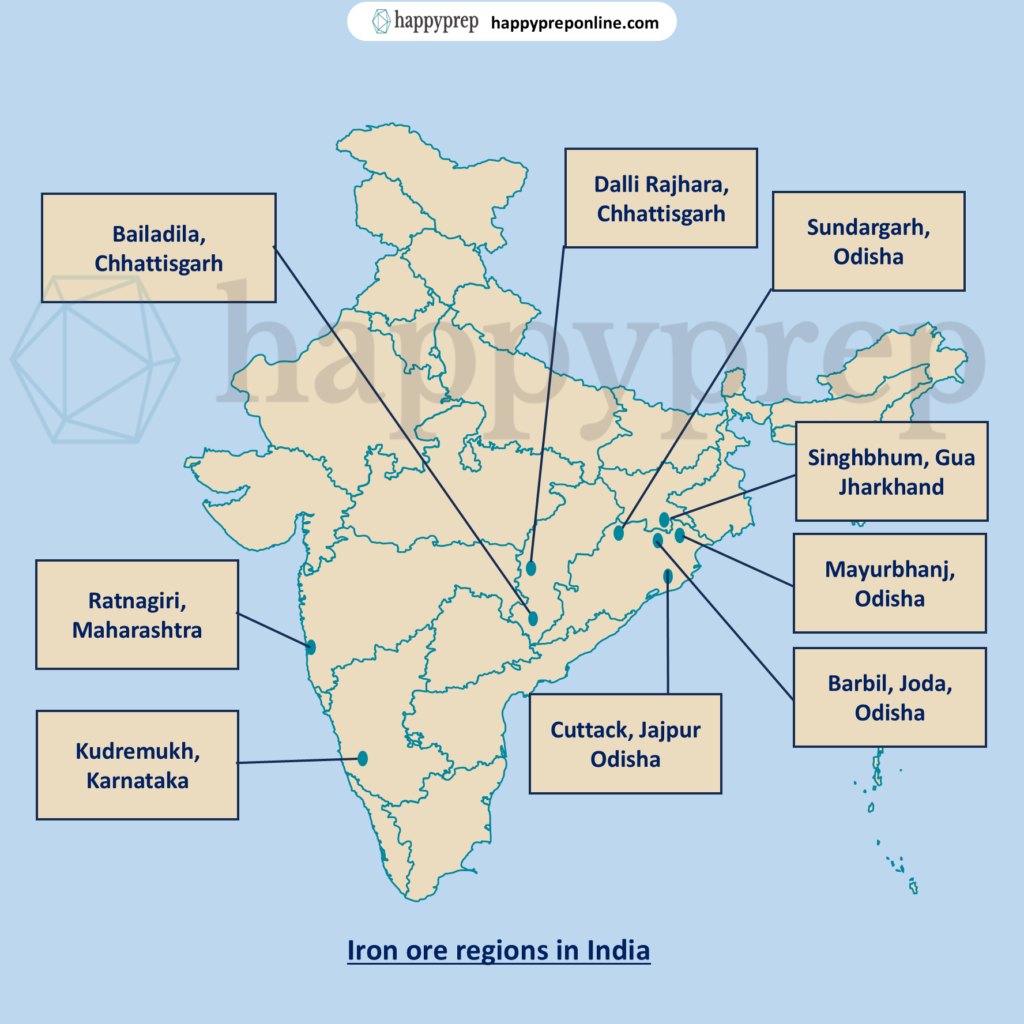

Distribution of Iron Ore in India

India

- The major iron ore producing states includes Odisha, Chhattisgarh, Karnataka and Jharkhand,

- high grade ores are found in Barbil region in Odisha, Singhbhum in Jharkhand and Kudremukh in Karnataka.

- Iron ore is mined in significant quantities in Goa, Tamil Nadu, Andhra Pradesh, Maharashtra, also.

Want to read some more articles?

-

Shanghai Cooperation Organization (SCO): Origin, Members, Facts, etc for UPSC and other exams

Shanghai Cooperation Organization (SCO): Origin, Members, Facts, etc for UPSC and other exams -

BRICS: Origin, members and others for UPSC, PSC & other exams

BRICS: Origin, members and others for UPSC, PSC & other exams -

BIMSTEC for UPSC: Origin, Members & More

BIMSTEC for UPSC: Origin, Members & More -

General Science for Competitive exams: UPSC, PSC, APFC, EO-AO, SSC, etc

General Science for Competitive exams: UPSC, PSC, APFC, EO-AO, SSC, etc -

THE TRADE UNIONS ACT, 1926 for UPSC EPFO APFC/EO-AO, ALC, and Other exams

THE TRADE UNIONS ACT, 1926 for UPSC EPFO APFC/EO-AO, ALC, and Other exams -

Understanding Macroenvironment: Marketing Environment in Principles of Marketing

Understanding Macroenvironment: Marketing Environment in Principles of Marketing -

Understanding Microenvironment: Marketing Environment in Principles of Marketing

Understanding Microenvironment: Marketing Environment in Principles of Marketing -

Interjections in English

-

Conjunctions in English

Recruitment notifications update!

-

Recruitment 2025: Recruitment for Teaching Staff in The School of Planning and Architecture, New Delhi - Vacancy, Posts, Grade Pay, etc

-

Recruitment 2025: Vacancies in Inter-University Centre for Astronomy and Astrophysics (IUCAA)

-

Recruitment 2025: Recruitment on Deputation basis in National Anti Doping Agency (NADA)

-

Recruitment 2025: Various vacancies in Artificial Limbs Manufacturing Corporation of India (ALIMCO)

-

Recruitment 2025: Various vacancies in Land Ports Authority of India

Copyright© 2024 | All rights reserved | Made in India